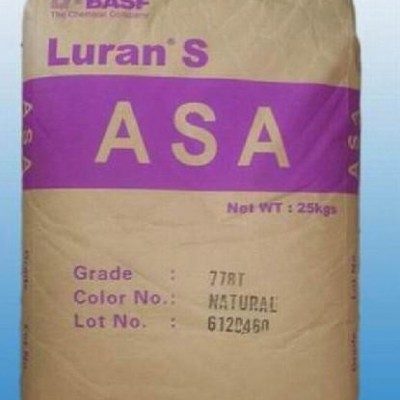

ASA Luran S 778T SPF30 德國(guó)巴斯夫

| 廠家(產(chǎn)地) | 德國(guó)巴斯夫 |

| 牌號(hào) | 778T SPF30 |

| 加工級(jí)別 | 注塑級(jí) |

| 特性級(jí)別 | 耐高溫,抗紫外線,耐候 |

| 銷售方式 | 品牌經(jīng)銷 |

| 類型 | 標(biāo)準(zhǔn)料 |

Properties of Luran S 778T SPF30

Property, Test ConditionStandardUnitValues

| Rheological Properties |

| Melt Volume Rate 220 °C/10 kg | ISO 1133 | cm³/10 min | 5 |

| Mechanical Properties |

| Izod Notched Impact Strength, 23 °C | ISO 180/A | kJ/m² | 20 |

| Izod Notched Impact Strength, -30 °C | ISO 180/A | kJ/m² | 4 |

| Charpy Notched Impact Strength, 23° C | ISO 179 | kJ/m² | 15 |

| Charpy Notched Impact Strength, -30° C | ISO 179 | kJ/m² | 4 |

| Tensile Stress at Yield, 23° C | ISO 527 | MPa | 54 |

| Tensile Strain at Yield, 23° C | ISO 527 | % | 3.4 |

| Tensile Modulus | ISO 527 | MPa | 2500 |

| Tensile Creep Modulus (1000h) | ISO 899 | MPa | 1250 |

| Elongation at Break (MD) | ISO 527 | % | 8 |

| Flexural Strength | ISO 178 | MPa | 80 |

| Hardness, Ball Indentation | ISO 2039-1 | MPa | 85 |

| Thermal Properties |

| Vicat Softening Temperature VST/B/50 (50°C/h, 50N) | ISO 306 | °C | 104 |

| Vicat Softening Temperature, VST/A/50 (50°C/h, 10N) | ISO 306 | °C | 113 |

| Heat Deflection Temperature A; (annealed, 1.8 MPa) | ISO 75 | °C | 103 |

| Heat Deflection Temperature B; (annealed, 0.45 MPa) | ISO 75 | °C | 106 |

| Coefficient of Linear Thermal Expansion | ISO 11359 | 10^(-6)/°C | 80 - 110 |

| Thermal Conductivity | DIN 52612-1 | W/(m K) | 0.17 |

| Electrical Properties |

| Dielectric Constant (100 Hz) | IEC 60250 | - | 3.9 |

| Dissipation Factor (100 Hz) | IEC 60250 | 10^(-4) | 90 |

| Dissipation Factor (1 MHz) | IEC 60250 | 10^(-4) | 330 |

| Volume Resistivity | IEC 60093 | Ohm*m | 1E12 |

| Surface Resistivity | IEC 60093 | Ohm | 1e+013 |

| Other Properties |

| Density | ISO 1183 | kg/m³ | 1070 |

| Water Absorption, Saturated at 23°C | ISO 62 | % | 1.65 |

| Moisture Absorption, Equilibrium 23°C/50% RH | ISO 62 | % | 0.35 |

| Processing |

| Linear Mold Shrinkage | ISO 294-4 | % | 0.5 - 0.9 |

| Melt Temperature Range | ISO 294 | °C | 240 - 280 |

| Mold Temperature Range | ISO 294 | °C | 60 |

| Injection Velocity | ISO 294 | mm/s | 200 |

| Drying Temperature | | °C | 80 |

| Drying Time | | h | 2 - 4

|